Research at the Robotics and Mechanisms Lab

There are many research topics which are currently being studied and developed here at the Robotics and Mechanisms lab. Most research is performed by Graduate or Doctoral students in the main areas of parallel manipulator kinematics, calibration of parallel manipulators, simulation, and optimization.

The majority of the recent work includes the study of parallel manipulators and the simulation of robotic systems. Study in the area of parallel manipulators is focused on improving the workspace characteristics (such as the size, quality, and force-moment capabilities) by researching kinematic and actuation redundancy. Also included in the study is kinematic calibration methods for reduced degree-of-freedom manipulators. In reference to the simulation of robotic systems, current research involves developing a computer simulated environment to analysis tethered underwater vehicles. In particular, flexible slender objects such as ROV tethers are being studied by determining the contact dynamics between convex and/or concave objects and by using new methods to find the seperation distance. Realistic tethered vehicle simulators have implemented recently developed contact dynamics models for such objects.

Introduction to Parallel Manipulator Kinematics

Parallel manipulators, also known as parallel mechanisms or parallel robots, are machines which have an end effector and a series of kinematic segments. The end effector is oriented in the work space through the motion of the kinematic chains and attaching a gripper, cutter, or torch as the end effector shows how beneficial parallel manipulators are to industry. In addition, parallel manipulators are far more accurate and reliable when completing repetitive tasks than humans due to high precision computer programs which simply need to run in a continuous loop.

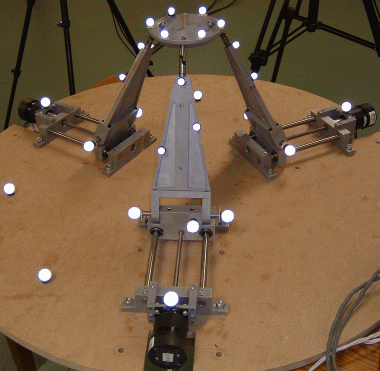

Each parallel manipulator is classified by the sequence of its kinematic pairs (joints); the most common types of kinematic pairs are prismatic, revolute, universal and spherical. How these kinematic pairs are implemented with one another determines how many degrees of freedom that mechanism has. So when classifying a parallel manipulator it is important to know how many degrees of freedom it has and what kind of kinematic pairs it utilizes. In the figure above is a 3 DOF, 3-PRS manipulator. There are three identical arms, hence why there is a 3 in the classification, and also there is a prismatic, revolute, and spherical joint (end effector). The prismatic joint is underlined because it is an actuated joint.

Introduction to Calibration of Parallel Manipulators

Calibration is an important field of study in parallel manipulators because it helps to improve the accuracy of the mechanism, in turn increasing the accuracy of the task at hand. Parallel manipulators already have a high repeatibility, and since the accuracy is lower, it is desireable for the accuracy to approach the repeatability. However accuracy is difficult to improve due to the individual errors in the kinematic parameters. These errors exist due to the difference between the theoretical kinematic model and how the manipulator is implemented in actual situations.

Before the accuracy of the manipulator can be improved the actual kinematic parameters must be determined using kinematic calibration of the manipulator. There are various methods available for kinematic calibration, including self-calibration with redundant sensors, self-calibration with mechanical constraints, variance accountable functions such as objective or error functions, and visual-based calibration such as a motion capture system.

Introduction to Simulation of Mechanical Systems

The simulation of mechanical systems is a convenient tool used with parallel manipulators. Not only does simulation model the mechanism on a user-friendly graphical interface but it also allows the user to solve the forward/inverse kinematic problems, to visualize a certain path trajetory for the model, and to determine important positions (singularities, contact, etc.) of the model during a specific motion. With the simulation of mechanical systems it is possible to gain alot of knowledge about a parallel manipulator and how it interacts with the workspace without having to make a prototype to test it.

Introduction to Optimization in Design

Optimization is a way of meeting certain design parameters such as specific velocities, maximum torque at a given position, or even minimizing the inertia of the machine. Parallel manipulators are no different, they require optimization to improve the operation under static and dynamic situations. Common areas of optimization for parallel manipulators include the reachable and dexterous workspaces, pose/velocity/acceleration profiles, and static/dynamic balancing.

There are a multitude of ways to optimize a design. Here at the RaM lab typical optimization research utilizes genetic algorithms, simulated annealing algorithms, and other global optimization algorithms. All of these algorithms achieve optimization in a similiar manner; an original design is compared to a modified design which was developed using one of the above algorithms, then they are compared and the more optimal solution is chosen.